Machinery & Technology

Our modern machinery fleet utilises state-of-the-art technology.

This brings two advantages; we can operate sympathetically with the environment, whilst reducing our carbon footprint and maintaining maximum efficiency.

In its simplest form, the core operations that happen on a modern arable farm are as follows:

- Cultivation

- Drilling

- Spraying

- Harvesting

Controlled Traffic Farming C.T.F

Over the entire farm we operate a 10m controlled Traffic Farming system (C.T.F).

This means we are only ever driving on the same wheeling’s within a field each year. This results in reduced compaction, therefore removing the need for cultivations to relieve the compaction, resulting in less carbon being released.

To enable this to happen, all of our tractors and the combine harvester use GPS and auto-steer technology to guarantee that we are running to a 2cm accuracy, year after year.

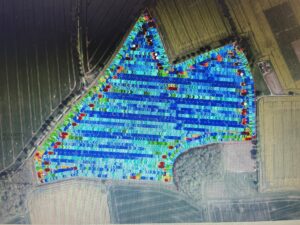

Collection Of Data

Where possible, we constantly try to collect and combine data to enable us to operate as effectively as possible. Currently our most important data comes from:

Combine yield maps

As the combine harvests, it uses GPS technology and flow meters to record the tonnages in exact parts of the field.

Soil maps

All of our fields have been scanned using an electrical conductivity scanner. As a result, we know what our soil make up is within individual zones within a field.

We know both the physical and chemical makeup of each zone within a field. This includes the amount of Organic matter, which is a very useful way of assessing a soils health. We are able to monitor this level to see how successful we are at improving the environment around us.

Using data

The collected data has a practical application.

By combining all of our data, we are able to vary our drilling and spray applications. This results in highly targeted operations and not just a broad brush approach.

Tractors

Tractors do not just provide the power to pull machinery – they are mini offices full of computers, with some tractors having three screens. In total, the farm department has a fleet of five tractors which get replaced on a regular basis.

Axion 960TT

Cultivations/Drilling Horse Power: 510

This is our main powerhouse tractor, weighing around 16.5t. It has tracks on the rear to help spread the weight to reduce compaction, and also improve traction.

The Anxion 960TT is 450Hp, which has replaced our 520Hp Xerion. It is still able to do the same job but with a reduced fuel usage, therefore reducing our carbon footprint.

New Holland T7.315

Cultivations/Harvest Horse Power: 315

This tractor is an all-rounder and is used mainly for secondary cultivations and if needed, grain carting.

New Holland T7.180

Cultivations/Harvest Horse Power: 180

Similar to the New Holland mentioned above, this is an all-round tractor. However, it also has the benefit that its tyres can be run at a very low pressures, which enable us to travel very lightly over the land once it has been drilled to avoid damage. It also has a detachable front-end loader, which helps with loading and unloading.

Fendt 724

Sprayer/Cultivation relief /Grain carting Horse Power: 240

The Fendt’s main purpose is to operate the sprayer. With its Vario transmission and ISOBus compatible joystick, the Fendt operates much the same as a self-propelled hydrostatic sprayer would.

It offers very high levels of operator comfort and excellent fuel efficiency.

JCB Telescopic loader

Loading/ unloading Horse Power: 150

Not strictly speaking a tractor! The loader is used all year around and its jobs vary greatly, from moving seed and fertiliser to handling grain.

Cultivations

Cultivations prepare the soil bed so that we can drill. Where possible we are trying to move away from intensive cultivation and instead work with nature. The most powerful and effective cultivators are earthworms!

Please see our soil health page to understand how our cultivations work to improve our soil quality.

Terrano

The Terrano is our primary cultivator. It is a very flexible machine and it can work at a range of depths from 2” down to 10”. This means that it can either be set to move a large or small amount of soil.

drill

Now that the soil bed has been prepared, we can place the seeds in the soil. We call this drilling.

Horsch Sprinter 10sw

10m wide

This drills all of our combinable crops on the farm – we are able to drill into stubble or moved soil. This allows a large amount of flexibility in our system.

The aim is to move more towards a direct drill system, ideally straight into the stubbles or cover crops without disturbing the soil. We are able to vary the seed rate delivered by using a pre-determined map, which is populated by assessing soil type and previous yield data. The GPS then provides a position so that the drill recognises where it is on the map, and applies the prescribed rate.

The drill can also place variable amounts of fertiliser, and is equipped with low disturbance changeable coulters, which minimises soil disturbance. In turn, it cuts down on the amount of weeds that germinate.

Spraying

Where possible, we always try to use natural means – spraying is a last resort. Sprays are used to help control weeds, insects, diseases and apply fertilisers.

Horsch Trailed LT5000

30m wide

This is where the perfect marriage between tractor and sprayer comes into its own – we have the ability to provide very accurate applications. This includes GPS nozzle shut-off, which minimises overlaps and stops the sprayer from being able to apply chemicals outside the target zone.

The boom operates using sensors along its length to keep at the desired height of 50cm from the target, to allow even coverage. It can even automatically change between nozzles to allow a constant pressure to be maintained as the machine speeds up or slows down – this helps to mitigate drift.

Combine

The combine is the machine that harvests the crop. We operate just the one combine.

New Holland CR9.90

30m wide Horse power:563hp

The combine cuts all of our OSR; Wheat; Oats and Beans totalling around 970Ha (2397ac) a year. This machine will typically cut 50ha (123ac) a day. The front tyres have been replaced by tracks to help spread the weight over a larger area, so saves on compaction and aids the stability of the cutter bar.

The cutter bar is slightly wider than 10m to allow us to stay on our 10m tramlines, but pick all the crop up as it can lean over when on long stems. Using GPS positioning, the onboard computer knows where the headset has already run, so will cut its recorded cutting width by the cm. This means that no overlap is recorded, therefore giving a very accurate yield picture back.